Mandel

Mandel dan Viernheim

Bu satıcı henüz bir firma açıklaması eklemedi.

Sn. (Bay) Dieter Mandel

Jägerstrasse 22

68519 Viernheim

Almanya

Benzer satıcılardan güncel teklifler

Küçük ilan

Malsch

Malsch

2.407 km

Şekillendirme makinesi - Dikey

WMWSTR 400

WMWSTR 400

Küçük ilan

Seon

Seon

2.373 km

Broş makinesi

ElmassP20-250-CNC

ElmassP20-250-CNC

Küçük ilan

Hamburg

Hamburg

2.510 km

Broş makinesi

HahndorfHRH 1200/4

HahndorfHRH 1200/4

Küçük ilan

Русе

Русе

945 km

Kanal açma makinesi

STANKO7M430

STANKO7M430

Küçük ilan

Almanya

Almanya

2.357 km

Şekillendirme makinesi

WelterWS 1250

WelterWS 1250

Küçük ilan

Bruchsal

Bruchsal

2.400 km

Broş Makinesi/FRÖMAG RAPIDA 463

FRÖMAGRapida 463 mit Indexiertisch

FRÖMAGRapida 463 mit Indexiertisch

Küçük ilan

Плевен

Плевен

1.017 km

Dikey Kanal Açma Makinesi

STANKO7D430

STANKO7D430

Küçük ilan

Düsseldorf

Düsseldorf

2.596 km

Broş makinesi

LorenzS360

LorenzS360

Küçük ilan

Dreieich

Dreieich

2.422 km

Broşlama makinesi - Kapalı - Dikey

HENNINGU 3 E

HENNINGU 3 E

Küçük ilan

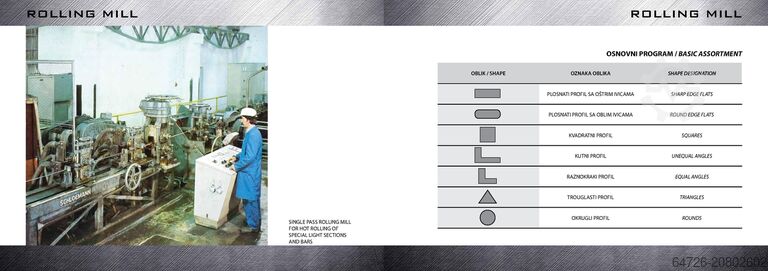

Zenica

Zenica

1.553 km

Haddehane

SCHLOEMANNroling mill

SCHLOEMANNroling mill

Küçük ilan

Almanya

Almanya

2.357 km

Şekillendirme makinesi

HahndorfREWK 86/14

HahndorfREWK 86/14

Küçük ilan

Mielec

Mielec

1.664 km

Broşlama makinesi

Karl Klink10.1250.69

Karl Klink10.1250.69

Küçük ilan

Ensisheim

Ensisheim

2.448 km

Dikey Kanal Açma Makinesi

GSPMORT 730

GSPMORT 730

Küçük ilan

Hofheim in Unterfranken

Hofheim in Unterfranken

2.306 km

Broşlama makinesi

WMW MeuselwitzRWI15x1400

WMW MeuselwitzRWI15x1400

Küçük ilan

Bruchsal

Bruchsal

2.400 km

Ravlama makinesi/Rausch RS6-1300

RAUSCHRS 6 / 1300

RAUSCHRS 6 / 1300

Küçük ilan

Bruchsal

Bruchsal

2.400 km

Raybalama makinesi/ VS 600

NutenstossmaschineVS 600

NutenstossmaschineVS 600

Küçük ilan

Naturno

Naturno

2.148 km

Broşlama makinesi

FrömagKZM32/300

FrömagKZM32/300

Küçük ilan

L'alcúdia de Crespíns

L'alcúdia de Crespíns

3.083 km

Broş makinesi

Klopp-CabeSK260

Klopp-CabeSK260

Küçük ilan

Korschenbroich

Korschenbroich

2.611 km

İplik haddeleme makinesi

LeistritzRT 400-CCA

LeistritzRT 400-CCA

Küçük ilan

Bruchsal

Bruchsal

2.400 km

Kanallama makinesi BEHR ST 150

BEHRST 150

BEHRST 150

Küçük ilan

Almanya

Almanya

2.357 km

İç işleme makinesi

Karl KlinkRISH 6,3.1000.500.T

Karl KlinkRISH 6,3.1000.500.T

Küçük ilan

Ennepetal

Ennepetal

2.561 km

Şekillendirme makinesi - Dikey

KLOPPSK 250

KLOPPSK 250

Küçük ilan

Hövelhof

Hövelhof

2.498 km

Broşlama makinesi

Karl KlinkRW 10 x 1350

Karl KlinkRW 10 x 1350

Küçük ilan

Striegistal

Striegistal

2.178 km

Dikey iç broşlama makinesi

Karl KlinkRISZ 25/630

Karl KlinkRISZ 25/630

Küçük ilan

Striegistal

Striegistal

2.178 km

Dikey iç broşlama makinesi

Karl KlinkRISH 16.1000.630

Karl KlinkRISH 16.1000.630