Kullanılmış aseptik hat, Tetra Pak için - 3600 adet/saatSOCO System

Kullanılmış aseptik hat, Tetra Pak için - 3600 adet/saat

SOCO System

Üretim yılı

2006

Durumu

Kullanılmış

Konum

Ukrayna

Resimleri göster

Haritayı göster

Makineye ait bilgiler

- Makine tanımı:

- Kullanılmış aseptik hat, Tetra Pak için - 3600 adet/saat

- Makine üreticisi:

- SOCO System

- Seri numarası:

- LC598

- Üretim yılı:

- 2006

- Durumu:

- kullanılmış

- Çalışma saati:

- 18.625 h

Fiyat ve Konum

- Konum:

- , Ukrayna

Ara

Teklif detayları

- Listeleme kimliği:

- A211-93420

- Referans no.:

- LC598

- Son güncelleme tarihi:

- 09.02.2026

Açıklama

Technical Specifications & Performance Data

This complete Tetra Fino Aseptic line is an integrated aseptic packaging solution developed by Tetra Pak for liquid food applications. The core filling machine was built in 2006 and is complemented by downstream packaging equipment. Designed for industrial packaging and beverage production, it offers reliable second-hand performance with hygienic processing and efficient material flow control.

Production speed: up to 3,600 packs/hour

Container type: carton-based aseptic packaging (Tetra Fino Aseptic family)

Supported volumes: 0.2 L to 1.0 L (examples: 0.2 L, 1.0 L)

Currently processed main product: Milk

Main filler year of manufacture: 2006

Additional module: SOCO System unit, year of manufacture 2014

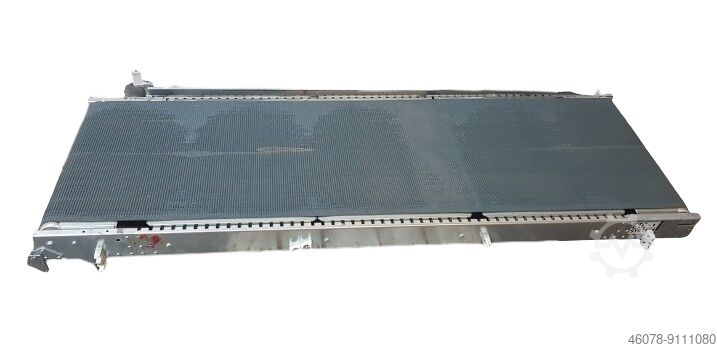

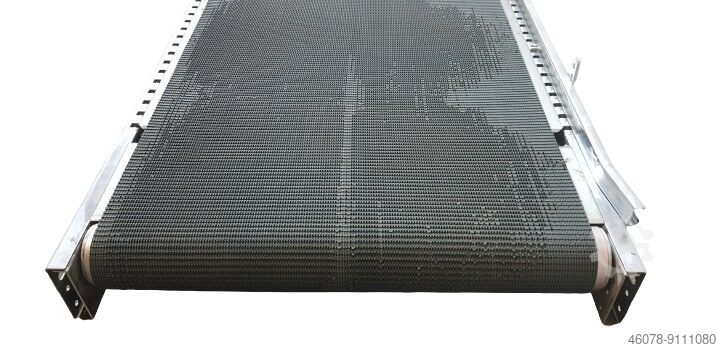

Accessories: trolley for packaging with roll holder, ABC valve, 1 m chain conveyor

Dksdjyh E Apspfx Afmeh

Advanced Automation & Control Systems

The line includes an industrial control panel for central management of filling and downstream handling. The aseptic filler integrates automated process sequences for sterilization, filling, and sealing under controlled conditions. Operator safety interlocks and machine guards support secure operation, while standardized HMI navigation simplifies recipe selection and format changes. The system architecture is designed for quick restarts and consistent availability in demanding environments.

Integration Capability in Production Lines

This used filling line is configured for inline operation, connecting the aseptic filler with conveyors and a SOCO System packaging module. It supports integration of typical ancillary equipment such as product discharge systems, cap or straw applicators, and end-of-line packaging machines. Format changes enable multiple carton volumes in the 0.2 L to 1.0 L range, providing multi-product flexibility for milk and juice production. The conveyor layout ensures gentle product transfers and balanced accumulation between stations.

Machine Condition & Maintenance History

The equipment is stated to be in production with overall good condition. Continuous operation with milk indicates stable performance and consistent hygiene compliance. The 2006 filler and 2014 downstream module are maintained to preserve aseptic integrity and packaging quality, making this used industrial plant a strong candidate for fast recommissioning.

Operational Performance & Versatility

Optimized for liquid food, the line supports aseptic packaging of products such as milk and juices in cushion/pillow-type Tetra Fino Aseptic format. Main advantages include extended shelf life at ambient temperature without preservatives, multilayer high-barrier materials, and hermetic sealing. The layout offers reliable filling accuracy, gentle product handling, and consistent quality, suitable for beverage production requiring long shelf life and robust logistics.

Installation Requirements & Site Preparation

The syst...

Bu ilan otomatik olarak tercüme edildiğinden bazı çeviri hataları oluşmuş olabilir.

This complete Tetra Fino Aseptic line is an integrated aseptic packaging solution developed by Tetra Pak for liquid food applications. The core filling machine was built in 2006 and is complemented by downstream packaging equipment. Designed for industrial packaging and beverage production, it offers reliable second-hand performance with hygienic processing and efficient material flow control.

Production speed: up to 3,600 packs/hour

Container type: carton-based aseptic packaging (Tetra Fino Aseptic family)

Supported volumes: 0.2 L to 1.0 L (examples: 0.2 L, 1.0 L)

Currently processed main product: Milk

Main filler year of manufacture: 2006

Additional module: SOCO System unit, year of manufacture 2014

Accessories: trolley for packaging with roll holder, ABC valve, 1 m chain conveyor

Dksdjyh E Apspfx Afmeh

Advanced Automation & Control Systems

The line includes an industrial control panel for central management of filling and downstream handling. The aseptic filler integrates automated process sequences for sterilization, filling, and sealing under controlled conditions. Operator safety interlocks and machine guards support secure operation, while standardized HMI navigation simplifies recipe selection and format changes. The system architecture is designed for quick restarts and consistent availability in demanding environments.

Integration Capability in Production Lines

This used filling line is configured for inline operation, connecting the aseptic filler with conveyors and a SOCO System packaging module. It supports integration of typical ancillary equipment such as product discharge systems, cap or straw applicators, and end-of-line packaging machines. Format changes enable multiple carton volumes in the 0.2 L to 1.0 L range, providing multi-product flexibility for milk and juice production. The conveyor layout ensures gentle product transfers and balanced accumulation between stations.

Machine Condition & Maintenance History

The equipment is stated to be in production with overall good condition. Continuous operation with milk indicates stable performance and consistent hygiene compliance. The 2006 filler and 2014 downstream module are maintained to preserve aseptic integrity and packaging quality, making this used industrial plant a strong candidate for fast recommissioning.

Operational Performance & Versatility

Optimized for liquid food, the line supports aseptic packaging of products such as milk and juices in cushion/pillow-type Tetra Fino Aseptic format. Main advantages include extended shelf life at ambient temperature without preservatives, multilayer high-barrier materials, and hermetic sealing. The layout offers reliable filling accuracy, gentle product handling, and consistent quality, suitable for beverage production requiring long shelf life and robust logistics.

Installation Requirements & Site Preparation

The syst...

Bu ilan otomatik olarak tercüme edildiğinden bazı çeviri hataları oluşmuş olabilir.

Belgeler

Tedarikçi

Not: Ücretsiz kaydolun veya giriş yapın, tüm bilgilere erişmek için.

İlk kayıt tarihi: 2021

İstek gönder

Telefon & Faks

+39 344 0... ilanlar

Bu ilanlar da ilginizi çekebilir.

Küçük ilan

Krefeld

Krefeld

2.611 km

Rulo konveyör

Soco System90 Grad Rollenbahnkurve

Soco System90 Grad Rollenbahnkurve

Küçük ilan

Sevenum

Sevenum

2.652 km

Kutu konikliği

SOCOT01

SOCOT01

Küçük ilan

Janville

Janville

2.853 km

Katlama ünitesine sahip bant kapama makinesi

Soco SystemF-100-P

Soco SystemF-100-P

Küçük ilan

Wiefelstede

Wiefelstede

2.603 km

Karton mühürleyici

Soco SystemT-10

Soco SystemT-10

Küçük ilan

Wiefelstede

Wiefelstede

2.602 km

Karton mühürleyen

Soco SystemKartonbreite 530 mm

Soco SystemKartonbreite 530 mm

Küçük ilan

Wiefelstede

Wiefelstede

2.603 km

Koli bantlama makinesi

Soco SystemT-10

Soco SystemT-10

Küçük ilan

Würzburg

Würzburg

2.326 km

Soco silindirli konveyör, rulolu hat 1980-670-610

SOCO

SOCO

Küçük ilan

Würzburg

Würzburg

2.326 km

Soco makaralı konveyör 1980-670-610

SOCO

SOCO

Küçük ilan

Würzburg

Würzburg

2.326 km

SOCO ağır hizmetli bant konveyör bant...

SOCO

SOCO

Küçük ilan

Würzburg

Würzburg

2.326 km

SOCO ağır hizmet bantlı konveyör Bant...

SOCO

SOCO

İlanınız başarıyla silindi

Bir hata oluştu