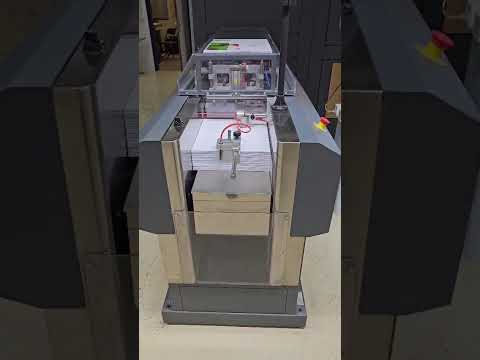

Dijital kitap üretim sistemiTECNAU

LIBRA 800

Dijital kitap üretim sistemi

TECNAU

LIBRA 800

Üretim yılı

2017

Durumu

Kullanılmış

Konum

Europa

Resimleri göster

Haritayı göster

Makineye ait bilgiler

- Makine tanımı:

- Dijital kitap üretim sistemi

- Makine üreticisi:

- TECNAU

- Model:

- LIBRA 800

- Üretim yılı:

- 2017

- Durumu:

- mükemmel (kullanılmış)

Fiyat ve Konum

- Konum:

- Europa

Ara

Teklif detayları

- Listeleme kimliği:

- A212-87107

- Referans no.:

- 40001.26

- Son güncelleme tarihi:

- 20.02.2026

Açıklama

HIGHLY AUTOMATED, MODULAR SYSTEM FOR DIGITAL BOOK PRODUCTION ('BOOK ON DEMAND') AND SHORT RUNS TECNAU LIBRA 800

Intended use: suitable for the layout and processing of short runs and single copies ('books of one') with varying sizes, page counts, and covers.

Performance: from run size 1; up to 800 copies per hour

Book format: min.: 100 x 125 mm / max.: A4

Thickness: min.: 2 mm / max.: 60 mm

Equipment / further details:

Line configuration:

1. Roll feed: Unwinder, merger, Dupla cutting machine, and book assembly station for the production of book blocks with 2-up printing

2. Sheet feeder: A variable number of loose sheets can be inserted as inserts into the book block. The sheets must be the same size and print run as the book block being processed.

3. Feed to the binding machine: Station for manual feed of pre-manufactured book blocks, transport with feed station, book turning module, and loading robot at the binding machine.

4. Variable binding machine for producing softcover books. The binding machine uses PUR glue on the spine and hot-melt glue on the sides.

5. Softcover case making machine configured with sheet cover feeder: Pre-printed cover sheets are fed in, trimmed at the front, side trimmed, and scored to the correct size so they match the thickness of the corresponding book block.

6. Cooling tower: Books are transported from the binding machine through the cooling tower to the three-knife trimmer.

7. Variable three-knife trimmer, suitable for trimming books of varying dimensions and with different types of covers.

8. Control software for system operation.

Finishing Line

The entire process is controlled via 2D Datamatrix codes. Through these codes, the system receives authorization for the following automatic settings and workflow management:

• Information on book dimensions and inserts (quantity and sequence)

• Setup of the binding machine (spine position, thickness, and length)

• Cover preparation: softcover → scoring, trimming, edge trimming

• Correct matching of book and cover

Kedpfx Adoylyhdedjdh

• Three-knife trimmer (knife positions are automatically set to book dimensions)

Bu ilan otomatik olarak tercüme edildiğinden bazı çeviri hataları oluşmuş olabilir.

Intended use: suitable for the layout and processing of short runs and single copies ('books of one') with varying sizes, page counts, and covers.

Performance: from run size 1; up to 800 copies per hour

Book format: min.: 100 x 125 mm / max.: A4

Thickness: min.: 2 mm / max.: 60 mm

Equipment / further details:

Line configuration:

1. Roll feed: Unwinder, merger, Dupla cutting machine, and book assembly station for the production of book blocks with 2-up printing

2. Sheet feeder: A variable number of loose sheets can be inserted as inserts into the book block. The sheets must be the same size and print run as the book block being processed.

3. Feed to the binding machine: Station for manual feed of pre-manufactured book blocks, transport with feed station, book turning module, and loading robot at the binding machine.

4. Variable binding machine for producing softcover books. The binding machine uses PUR glue on the spine and hot-melt glue on the sides.

5. Softcover case making machine configured with sheet cover feeder: Pre-printed cover sheets are fed in, trimmed at the front, side trimmed, and scored to the correct size so they match the thickness of the corresponding book block.

6. Cooling tower: Books are transported from the binding machine through the cooling tower to the three-knife trimmer.

7. Variable three-knife trimmer, suitable for trimming books of varying dimensions and with different types of covers.

8. Control software for system operation.

Finishing Line

The entire process is controlled via 2D Datamatrix codes. Through these codes, the system receives authorization for the following automatic settings and workflow management:

• Information on book dimensions and inserts (quantity and sequence)

• Setup of the binding machine (spine position, thickness, and length)

• Cover preparation: softcover → scoring, trimming, edge trimming

• Correct matching of book and cover

Kedpfx Adoylyhdedjdh

• Three-knife trimmer (knife positions are automatically set to book dimensions)

Bu ilan otomatik olarak tercüme edildiğinden bazı çeviri hataları oluşmuş olabilir.

Tedarikçi

Not: Ücretsiz kaydolun veya giriş yapın, tüm bilgilere erişmek için.

İstek gönder

Telefon & Faks

+41 71 54... ilanlar

İlanınız başarıyla silindi

Bir hata oluştu