Kullanılmış komple durağan şarap dolum hattı - saatte 8000 şişe (BPH)APE Impianti

Kullanılmış komple durağan şarap dolum hattı - saatte 8000 şişe (BPH)

APE Impianti

Durumu

Kullanılmış

Konum

İtalya

Resimleri göster

Haritayı göster

Makineye ait bilgiler

Fiyat ve Konum

- Konum:

- , İtalya

Ara

Teklif detayları

- Listeleme kimliği:

- A211-93520

- Referans no.:

- LC597

- Son güncelleme tarihi:

- 09.02.2026

Açıklama

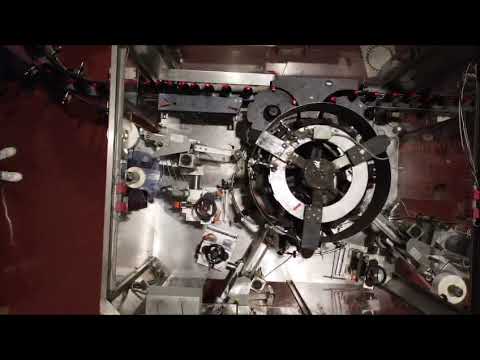

Technical Specifications & Performance Data

This used bottling line is designed for reliable beverage production and downstream industrial packaging at up to 8,000 bottles per hour. The configuration integrates APE Impianti carton handling with KOSME labelling technology, delivering robust performance for second-hand applications as well as flexible format control, as commonly required for glass and PET bottles.

Dkjdpfxeyh E Hus Afmsh

Production speed: 8,000 bottles per hour

Compatible formats: Typical carton packing pattern includes 12 x 0.75 L; additional formats can be handled with change parts

Containers: Designed for bottle handling; configuration suitable for PET and glass (cylindrical containers)

Labelling systems: KOSME STAR 720 12T (cold glue), KOSME EXTRA ADHESIVE 12T S3 E3 (self-adhesive)

Packaging modules: APE FORMA 2000 (carton erector), APE INCA 2010 (carton packer), APE INSER 2001 (partition inserter)

Electricals (labellers): 400 V, 50 Hz; installed power 4 kW (STAR 720 12T) and 8 kW (EXTRA ADHESIVE 12T S3 E3)

Weights (labellers): 2,650 kg (STAR 720 12T), 2,000 kg (EXTRA ADHESIVE 12T S3 E3)

Compliance: CE-marked components

Advanced Automation & Control Systems

The line employs modular automation across labelling and carton handling stations to ensure stable throughput. Operator-friendly controls on each module support rapid commissioning and format changes. The KOSME labelling machines feature standardised European electrical specifications (400 V, 50 Hz) and matched installed power ratings to guarantee precise label application at line speed. APE Impianti packaging modules offer synchronised movements and interlocked safety guards for downstream processes.

• Integrated start/stop logic and line accumulation for flow stabilisation

• Quick mechanical adjustments for format changeovers with guided setup steps

• Interlocked safety fencing and emergency stop at main machines

• Clear HMI/control panels for each machine, supporting format selection and diagnostics

Production Line Integration Capabilities

This production line is engineered for in-line operation with conveyors and buffering to achieve the 8,000 bottles per hour target. The dual labelling architecture—cold glue and self-adhesive—supports a broad range of label materials and presentation standards. Carton erecting, partition insertion, and packaging are fully integrated for efficient end-of-line handling, enabling consistent carton quality for logistics and warehousing.

• In-line configuration with compatibility to upstream/downstream equipment

• Cold glue and self-adhesive labelling flexibility for front/back and wraparound applications

• Carton erecting, partitioning, and packaging for 12 x 0.75 L pattern

• Suitable for multiple bottle sizes with appropriate change parts

Machine Condition & Maintenance History

This is a pre-owned bottling and packaging solution with components from years of manufa...

Bu ilan otomatik olarak tercüme edildiğinden bazı çeviri hataları oluşmuş olabilir.

This used bottling line is designed for reliable beverage production and downstream industrial packaging at up to 8,000 bottles per hour. The configuration integrates APE Impianti carton handling with KOSME labelling technology, delivering robust performance for second-hand applications as well as flexible format control, as commonly required for glass and PET bottles.

Dkjdpfxeyh E Hus Afmsh

Production speed: 8,000 bottles per hour

Compatible formats: Typical carton packing pattern includes 12 x 0.75 L; additional formats can be handled with change parts

Containers: Designed for bottle handling; configuration suitable for PET and glass (cylindrical containers)

Labelling systems: KOSME STAR 720 12T (cold glue), KOSME EXTRA ADHESIVE 12T S3 E3 (self-adhesive)

Packaging modules: APE FORMA 2000 (carton erector), APE INCA 2010 (carton packer), APE INSER 2001 (partition inserter)

Electricals (labellers): 400 V, 50 Hz; installed power 4 kW (STAR 720 12T) and 8 kW (EXTRA ADHESIVE 12T S3 E3)

Weights (labellers): 2,650 kg (STAR 720 12T), 2,000 kg (EXTRA ADHESIVE 12T S3 E3)

Compliance: CE-marked components

Advanced Automation & Control Systems

The line employs modular automation across labelling and carton handling stations to ensure stable throughput. Operator-friendly controls on each module support rapid commissioning and format changes. The KOSME labelling machines feature standardised European electrical specifications (400 V, 50 Hz) and matched installed power ratings to guarantee precise label application at line speed. APE Impianti packaging modules offer synchronised movements and interlocked safety guards for downstream processes.

• Integrated start/stop logic and line accumulation for flow stabilisation

• Quick mechanical adjustments for format changeovers with guided setup steps

• Interlocked safety fencing and emergency stop at main machines

• Clear HMI/control panels for each machine, supporting format selection and diagnostics

Production Line Integration Capabilities

This production line is engineered for in-line operation with conveyors and buffering to achieve the 8,000 bottles per hour target. The dual labelling architecture—cold glue and self-adhesive—supports a broad range of label materials and presentation standards. Carton erecting, partition insertion, and packaging are fully integrated for efficient end-of-line handling, enabling consistent carton quality for logistics and warehousing.

• In-line configuration with compatibility to upstream/downstream equipment

• Cold glue and self-adhesive labelling flexibility for front/back and wraparound applications

• Carton erecting, partitioning, and packaging for 12 x 0.75 L pattern

• Suitable for multiple bottle sizes with appropriate change parts

Machine Condition & Maintenance History

This is a pre-owned bottling and packaging solution with components from years of manufa...

Bu ilan otomatik olarak tercüme edildiğinden bazı çeviri hataları oluşmuş olabilir.

Belgeler

Tedarikçi

Not: Ücretsiz kaydolun veya giriş yapın, tüm bilgilere erişmek için.

İlk kayıt tarihi: 2021

İstek gönder

Telefon & Faks

+39 344 0... ilanlar

Bu ilanlar da ilginizi çekebilir.

Küçük ilan

Fumane (Verona)

Fumane (Verona)

2.126 km

Kasa Paketleyici

APE ImpiantiInca 2001

APE ImpiantiInca 2001

Küçük ilan

Fumane (Verona)

Fumane (Verona)

2.126 km

Kasa Montajcısı

APE ImpiantiForm 1200 HM

APE ImpiantiForm 1200 HM

Küçük ilan

Fumane (Verona)

Fumane (Verona)

2.126 km

Kasa Paketleyici

APE ImpiantiINCA 2000

APE ImpiantiINCA 2000

Küçük ilan

Fumane (Verona)

Fumane (Verona)

2.126 km

Kasa Montajcısı

APE ImpiantiForm 2000 HM SX

APE ImpiantiForm 2000 HM SX

Küçük ilan

Fumane (Verona)

Fumane (Verona)

2.126 km

Kasa Montajcısı

APE ImpiantiFORM1500 HMB

APE ImpiantiFORM1500 HMB

İlanınız başarıyla silindi

Bir hata oluştu